Classification and separation activities, though fundamental, play significant roles in the global operations of mineral processing. A vibrating screen machine is used in this process with the function of separating the material by its size for more processing. This industrial screening machine is very crucial in industries like mining, construction and recycling among others since it helps them to sieve large quantities of materials within a short time and with a high efficiency. This paper aims at presenting an analysis of the evolution of the vibrating screen machines, their uses in mineral processing, their advantages, as well as the ways in which they enhance functional performance.

Key Applications of Vibrating Screen Machines in Mineral Processing

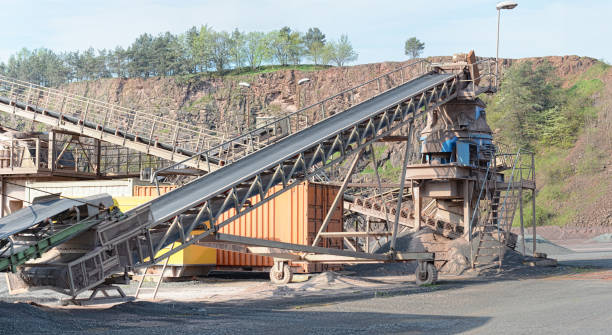

Vibrating screen machines are used in a wide manner in mineral processing for various purposes based on operational requirements. One of their prime applications is used in the estimation and separation of ores into size classes. For example, in the process of mining, as in gold mining, copper and iron mining, the use of vibrating screens to separate minerals and waste rocks. This makes certain that only the right raw material goes through the next stage of the processing. Another important use is of vibrating screens in the dewatering processes where mineral slurries are treated by eliminating excessive moisture. This process is important for enhancing issues such as material flow and cutting down transport costs. Also in the material separation process, vibrating screens are used in the scalper section to reject any large particles into the mill which might cause more damage to the grinding equipment. In these applications, high quality industrial screening equipment with accurate and dependable performance are vital to complement the successful strategies of mineral processing.

Benefits of Using Vibrating Screen Machines in Mineral Processing

There are plenty of reasons why utilizing the vibrating screen machines to be one of the most popular mechanic processing equipment for mineral industries. An important strength is they provide optimal handling of high loads coupled with the capability to sort materials accurately. This avoids wastage of a lot of time and resources and also ensures that no company is overtaken due to negligence. Vibrating screens are also very mobile and can handle an extensive variety of applications – both wet and dry materials, coarse or fine. If that is not enough, then the fact that they are both durable and reliable should be enough to convince people to consider them. Incorporated with durable and abrasion proof materials, vibrating screens are specifically developed for mineral processing plants. Also, the present models are equipped with energy-efficient motors and automatic controls to enhance efficiency and effective cost of operation without straining the machinery’s performance. They also possess simple curb maintenance requirements such as instant accessibility panels and modularity for easier and quicker inspection and replacement. When you implement a vibrating screen machine in your minerals processing operation, they will be recommended to give the facility higher productivity, lower operational cost and better quality materials.

How to Choose the Right Industrial Screening Equipment

It is essential for a mineral processing operation to utilize the proper industrial screening equipment to be successful. When choosing which screen to use, think about the material to be screened, as different screens work best on different particle sizes, moisture and kind of material. For instance, thin materials that have a small mass will need a high-frequency screen while huge and massive materials will need both, high amplitude and thick meshes. Capacity is another essential aspect of its consideration. Make sure that the throughputs which the selected vibrating screen is going to handle; should go hand in hand with efficiency and accuracy. Select equipment with operating vibratory frequency, amplitude, and deck tilt; these are functional factors that help you switch the screen to suit your processing needs. Moreover, durability and maintainability should be at the top of your list. Advanced processing is used in the development of industrial screening equipment and use of high resistant material enhances durableness thus reducing the usability challenges hence increasing reliability of the equipment. Another factor is the choice of supplier where it is always advisable to deal with a knowledgeable supplier who can guide you on the right model and product to buy and also the one who will undertake to service the vibrating screen always.

The Future of Vibrating Screen Machines in Mineral Processing

As industries continue to demand greater efficiency and precision, the role of vibrating screen machines in mineral processing will only grow. It is at this stage that research in development of improved screening equipment is achieved with components including automation controls, operating in real time, and a self-cleaning screen. These inventions help to enhance efficiency, lower the expense of operations, and decrease the overall pollution; these are the tools that should be implemented in the modern mineral-processing centres. Also, the needs for sustainability have led to implementation of low power techniques that enable efficient power consumption for the same level of output. Ensuring that means investing in leading-edge screening gear that is technically available, which accelerates operational effectiveness while also promoting smart resource utilization.

Conclusion

The vibrating screen machines are used in different industries mainly in the extraction of minerals and finding uses in screening of materials among various fields. The sizing and classification functions mainly involve the use of these devices while dewatering and scalping are also of great importance in mineral extraction and beneficiation processes. By knowing the uses and advantages of vibrating screens together with the methods in selecting the appropriate industrial screening machine, you can improve your production processes and therefore yields will be enhanced. Whether engaged in ore dressing, crushed stone production, or thickened slurry, investing in high efficient vibrating screen machines helps to raise the benefit and create stable high-quality products. The technological changes in the screening technology have advanced this year, and it is the right time to reinstall your mineral processing systems to better efficiency. Working with a supplier means that you obtain quality, long-lasting equipment perfect for your goal to have a competitive advantage in the market.